Matter

I’ve been doing a lot of 3D printing lately. No, I didn’t get a new printer for the holidays, but I’ve been on streak of productivity and my setup has allowed me to do more with less time. That got me thinking about how 3D printing is an enabler for Anticryptography.

Storage

Like most people, this is a good time of year to declutter and organize. This year I went through a lot of old papers that I didn’t need anymore (receipts for under $10 from the 90s, etc). Some of those things I can get rid of of because I have scanned them into the digital form. So long as I’m using a format friendly to Anticryptography it should be good for life (mine or the file’s). PDF/A (not the default PDF format from most Adobe tools, but an option across the board and one you should default to) should be readable for the rest of the century.

I can cut those to optical disks, keep them on hard drives, or roll them off to tape (I haven’t done that one in a while). All of those take space, but not much. A single M-disk in CD case can be thrown in a drawer or safety deposit box and forgotten for decades. The space becomes a non issue until you get into Terabytes.

Physical items though are real modern problem. We have many things, and a large fraction of those we want to keep. The rise of self storage sites on fairly prime real estate are the economic evidence of that. Some things you store for sentimental reasons. Other items because you might need them in the future. Then there are the classes of items that you just need to use on a regular basis. Tools, furniture, that doohickey you put on a machine to make it stop shaking, etc.

That last class of things are the ones that take up space in our active life. We have them nearby and at the ready. Others we buy and have shipped to us overnight. Moving those items around in vehicles to get them to you ASAP is a large industrial effort, and maybe one we don’t always need.

3D printing

There has been an idea that we will just create what we need, when we need it. Star Trek promised this with the replicators and the 3D printing industry has used that as an inspiration since the beginning. What’s not to like about it. No need to store something just in case, just make it when you need it.

Right now we can do that with solid objects and simple mechanical systems. Many people have 3D printers and laser cutters in the home and can make small items in a matter of hours. The materials are dropping in price and getting more impressive in engineering quality.

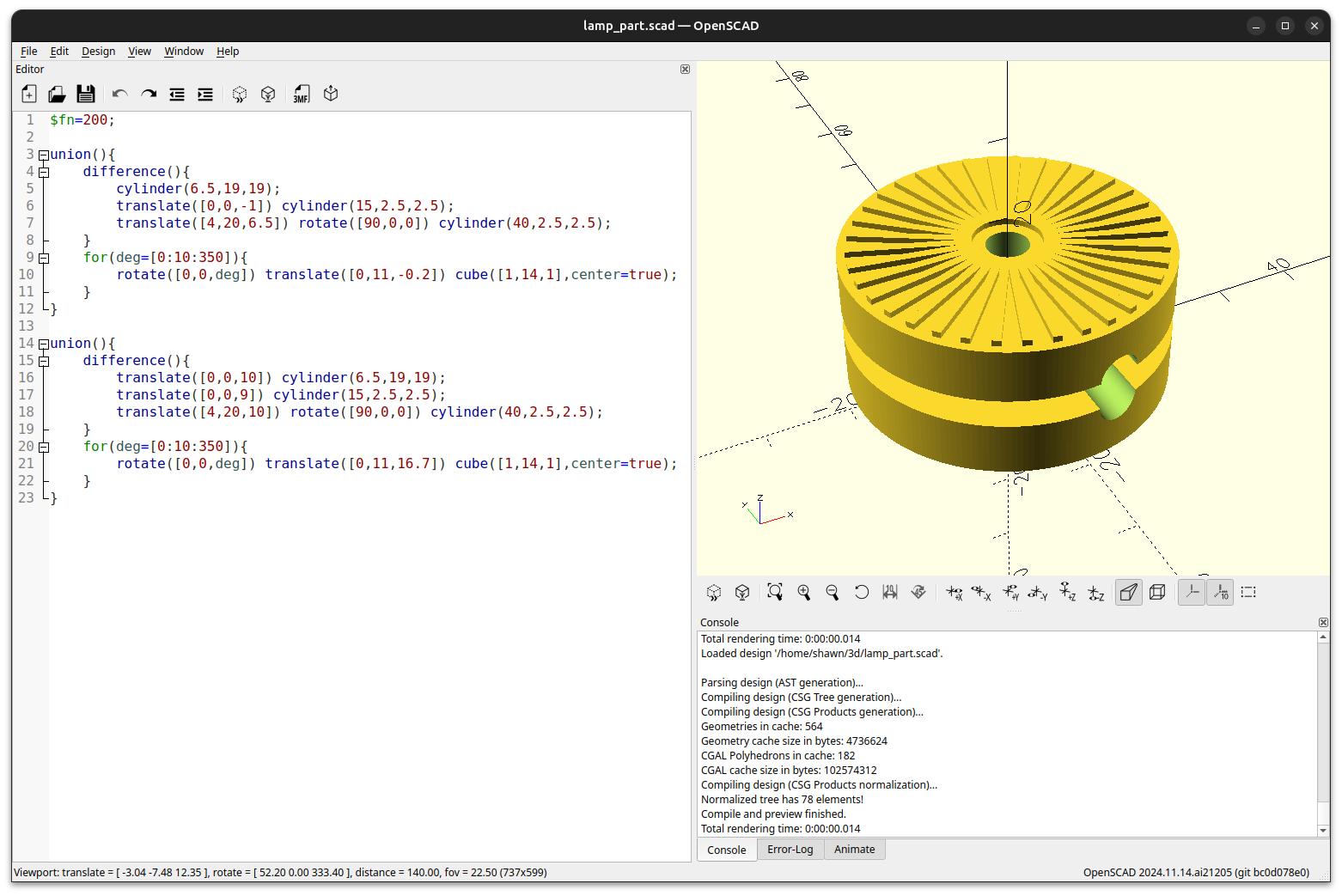

For example, I have a magnifying lamp on a multi joint arm with springs. The collar for the light and lens broke. I couldn’t find that part for sale anywhere. My only option was to throw out the lamp and buy a new one. Instead I measured the old broken part, laid out a new one in OpenSCAD and printed it.

Three tries later I have a working lamp and avoided wasting the perfectly good parts that didn’t break. It has held up for a year and looks like it will be good for years to come.

It would make no sense for the company that makes the lamps to sell the part. They want to sell you a new lamp, and setting up distribution for the part would probably be in excess of the lamps value. They could sell the 3D design for someone to print a replacement part. The cost of selling the design would approach 0. Given the profit in lamp sales, the idea is mostly academic in this case.

What we can take away from this example is that a physical object can be stored as a small file on my computer. That’s 23 lines of code! The STL file that represents the solid design is 140K. Sure that’s a huge increase over the code, but it is still nothing by today’s standards. If my lamp breaks again, I’m 4 hours and 50 cents of plastic away from having the new part. Even if the company sent it to me for just the shipping cost, it couldn’t compete.

To be digital …

This idea won’t let me keep sentimental items in digital form, but we need to look at where it can be applied. There are a range of tools that I don’t need very often and I think that is the first place to look.

I’ve used some of the press breaks for bending sheet metal. Basically print the 2 sides and start bending. Once you are done, you can throw away the plastic tool (it cost a few dollars at most and it has a limited life span), or you can throw it in a drawer for a few more uses later on. Need a different angle or shape? Download another and print it out. Probably be using it before a part can be shipped overnight.

Need a more complex shape? Design the press and print it like this guy did in the animation above. Need to send that to someone on the other side of the world? Email is perfect if the receiving party can do the work. When we have a presence outside of low Earth orbit, it will be criminally expensive to send a physical item that can be printed and formed from a digital file.

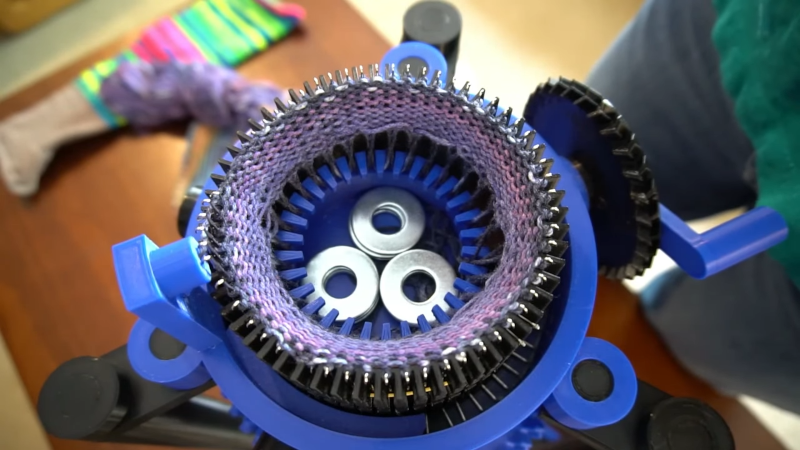

This idea can get crazy. Want to make some socks? There is a 3D printable machine for that. Sure it uses some metal parts, but almost all of those are off the shelf enough that a good shop has them sitting around. This beast is complex enough that you can have one shipped to you long before you could print and build one, unless those socks are to be made on Mars (we live in interesting times).

… or not to be digital?

Looking at history we can see where these options could have been useful. The one that comes to mind immediately is the Saturn V rocket.

The engines used for the different stages were marvels of the times and still represent an engineering bar that is hard to exceed. We have the blueprints and some physical artifacts stored in special conditions, but none of that is useful in building new ones. They can be used as reference materials in redesigning the engines, but at a cost that would exceed starting from scratch.

Rocket engines can now be printed. Not on my printer at home, but on special printers. The cool thing, those special printers are made with parts that are digitally available and produced by subtractive and additive methods. Given the right files the production of those rockets can be bootstrapped with tooling and materials. We have never before been in that situation and we will always be in it moving forward.

The future…

Ok, so we can build tools from digital files that build more complex items. As we move forward in time all mass produced items will be the product of a similar tower of files and machines. Someone with the files, some basic machines, materials and time, can build anything. That is the physical side of Anticryptography in a nutshell.

Credits

The cover image is of a hydrogen (the most abundant matter and present in many of molecules your deal with daily) discharge tube from Wikipedia, and used under the license terms are that link.

Other images are taken from the linked articles.